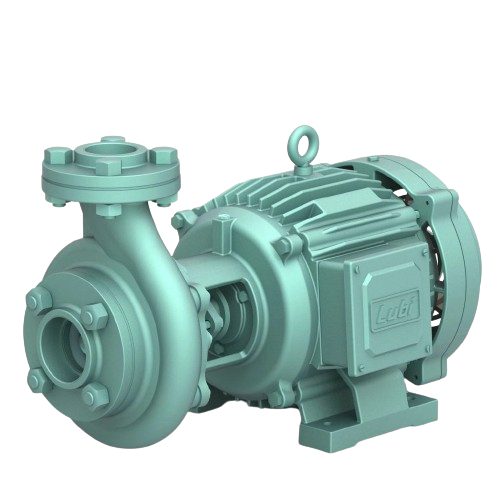

Monoblock Pumps

OUR PRODUCTS

Monoblock Pumps

According to IS-648, the laminations are made of non-oriented silicon steel.

The volute, impeller, adaptor, stator body, and end shield must be made of close-grained cast iron with a high tensile strength and a very smooth surface finish, resulting in minimal friction losses.

Motor windings must be vacuum-impregnated with synthetic varnish for increased moisture resistance. Superior mechanical shaft seal for longer life and effective sealing against water leakage.

The electric motor is pressure die-cast and made of electrical-grade aluminum. Grease Lubricated anti-friction ball bearings shall be fitted at both ends to withstand radial and axial loads. They are precisely machined on modern machine tools to give you years of reliable operation.

Better insulation materials are used to ensure that the pump set can withstand high-temperature increases.